Profiling rolling is an advanced and efficient technology for the production of steel profiles, which guarantees precision and versatility. It allows strip thicknesses from 0.5 to 5 mm, lengths up to 27,000 mm and heights up to 100 mm to be processed. The process, carried out cold, progressively deforms the strip to the desired shape, maintaining or in some cases even improving the characteristics of the material.Thanks to our innovative capacity, we produce more elaborate shapes than traditional methods, simplifying further processing and increasing the quantities produced. This results in profiles with optimised thickness, complex or variable height sections, optimising costs and making your production more efficient.Profiling rolling advantagesHigh accuracy and repeatability: precise and uniform profiles with minimal tolerances, thanks to cold forming that maintains constant dimensions and quality.Material optimisation: roll forming minimises scrap, improves steel properties and ensures sustainable strength, durability and efficiency.Design flexibility: this technique creates articulated and customised geometries, with variable thicknesses and complex sections, improving productivity and flexibility.Ideal for high-volume production (from around 2000 metres), roll forming allows additional processing such as drilling, slotting, embossing or thread insertion directly in-line. The result is a highly competitive, cost-optimised range of possibilities.

Processes

Processes

Unique machining for unique requirements

With over 30 years of experience in the industry, Profilsystem excels in offering targeted customisation services designed to tailor profiles to the specific requirements of each project. Our metal design and machining capabilities enable the creation of profiles with precise cuts, optimal thicknesses and unique characteristics. This approach not only improves the efficiency and functionality of the products, but also increases their durability.

At Profilsystem, we strive to fully understand our customers' needs and anticipate technical challenges through customised solutions. Our processes are designed to ensure that each profile is precisely manufactured to integrate seamlessly into your most complex and ambitious projects. Whether you are designing an innovative architectural structure or a sophisticated industrial component, we are ready to provide you with the quality and reliability you need to make your project a success.

Learn more about our machining to realise your most ambitious metalworking goals.

Our processes

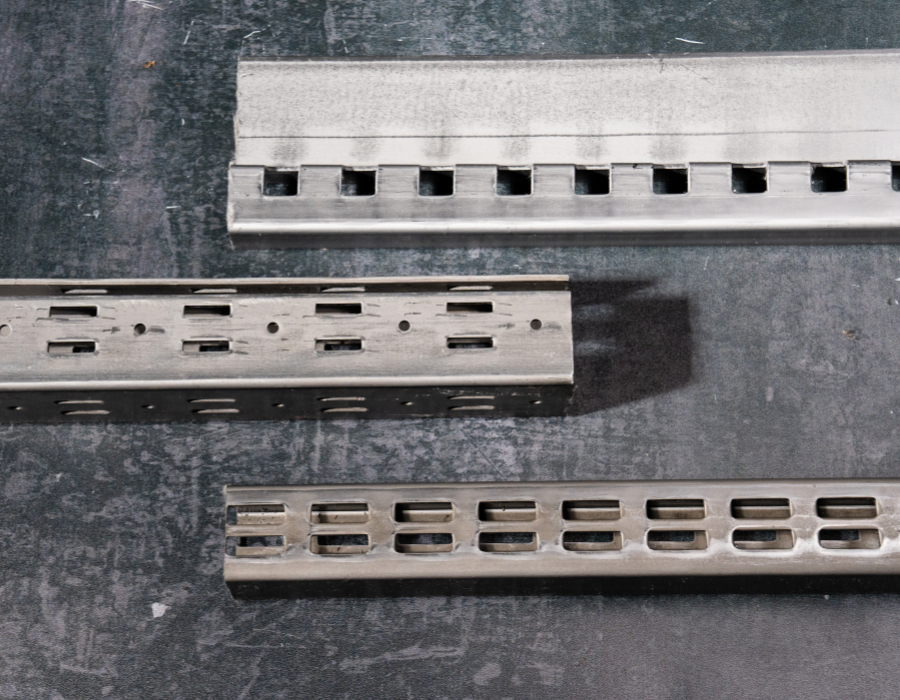

Perforation

Strip perforationis an advanced technology we use to enhance competitiveness and reduce production times. This process allows for the creation of shaped and customized holes according to designs, completing the required profiles without the need for additional work. Thanks to high-performance machinery equipped with photo-cellular technology, we guarantee millimetric precision with decimal tolerances that meet the most stringent requirements. The applications are extensive: from uprights for shelving, electrical cabinets, and displays, to profiles for fences, movable and equipped walls, and photovoltaic systems. We can perform continuous pitch perforation, with or without pitch jumps, maintaining precise distances between head and tail as per customer specifications. Additionally, we offer laser perforation, ideal for jobs requiring an even more specific finish.Advantages of strip perforationProduction Efficiency: Reduced time thanks to a direct process without rework.Design Flexibility: Ability to customize holes and distances based on project requirements.Guaranteed Precision: Advanced machinery ensures tight tolerances and flawless machining.With strip perforation, we provide a technological and highly customized service, aligning with our mission to create added value and synergies with our customer partners.

Joining techniques

To meet the needs of sectors such as furniture, industrial roller shutters and vehicle cabins, we offer advanced joining techniques such as stapling, clinching and laser welding. These processes make it possible to produce closed metal profiles in galvanised, pre-painted or plastic-coated steel, guaranteeing precision and durability.Crimping, with a double fold turned and pressed dry, creates hermetically sealed joints by means of grain or herringbone micro-incisions, keeping the surface coatings intact. Clinching uses controlled compression to join adjacent flaps, pressing one on top of the other with pressure proportional to the thickness of the tape. When used together, these techniques offer greater overall strength while fully preserving the quality of the coatings. Laser welding is excellent for those who want a homogenous, rust-resistant joint that eliminates the risk of oxidation. Thanks to this feature, it is ideal for applications requiring a precise finish and long-lasting performance. We offer a combination of technologies to meet every design requirement, balancing strength, precision and aesthetics.Advantages of advanced jointsPrecision and versatility: Profiles with complex shapes and punched to decimal tolerances.Cost and time savings: Elimination of additional machining thanks to ready-made profiles.Protection of the coating: Maintaining surface quality thanks to stapling and clinching.Thanks to innovative technologies and attention to detail, we are a reliable partner for closed metal profiles designed for functionality and durability.

Marking

Among the many possibilities for customising steel and metal profiles, marking stands out as an essential process for ensuring uniqueness and functionality of products. This process allows lettering, company logos, CE marking and casting codes to be stamped directly on the profile surface, offering added value in terms of brand recognition and optimal traceability throughout the product life cycle. Marking can be achieved through two specific technologies. The first involves the use of a pressure marking roller which, in motion, impresses the characters on the profile thanks to the rotation of the roller with reliefs. This method guarantees uniform and precise marking, ideal for smooth surfaces. The second technique, on the other hand, uses stamping, a solution particularly suited to perforated profiles. In this case, the process combines drilling and marking in a single step, creating direct engravings on the metal strip for complete and effective customisation.Advantages of the marking processAdvanced customisation: The possibility of adding lettering or logos allows the profiles to be distinguished and adapted to the specific needs of each customer.Brand recognition: Marked profiles become a communication vehicle for corporate identity, increasing brand visibility.Precision and durability: The technologies employed ensure sharp and durable markings that are resistant to wear and external agents.With this processing, we offer tailor-made solutions that combine functionality and design, confirming our commitment to quality and customer satisfaction.

Cutting

Our roll forming systems offer in-line cutting systems, such as slow sawing and guillotine cutting, for clean, burr-free metal profiles. The slow saw is ideal for closed or welded iron profiles, while the guillotine cut is suitable for open profiles. We can handle profiles of varying lengths to achieve the desired size, allowing the profiles to be directly integrated into the production cycle with precise tolerances of up to ±1 mm for standard or drilled profiles. Thanks to advanced technology and thirty years of experience, we provide flexible and customised solutions, always oriented towards customer needs.Advantages of cuttingReduced waste: Precision cutting optimises material utilisation, minimising waste and improving production efficiency.Clean and secure edges: Machining guarantees extremely accurate cuts and imperfection-free surfaces, ready for use without the need for further finishing.Material versatility: The cutting technology is compatible with different types of steel, including those with variable thickness and special coatings, while maintaining the technical characteristics of the material.With this processing, we provide customers with a highly technological and customised cutting service, capable of responding to the most complex challenges of the market, consolidating its role as the ideal partner for innovative and customised projects.

Plastic coating

Plasticisation is an advanced process that applies a protective plastic coating to the surface of steel profiles with extreme precision. This treatment not only improves the aesthetics of the product, but also makes it highly resistant to wear, weathering and corrosion, preserving its structural quality and extending its life cycle. Ideal for electrical applications, such as battery racks, plastic coating provides superior insulation and protection, making it perfect for applications requiring durability and high performance.Advantages of plastic coatingCorrosion resistance: The plastic coating protects steel from atmospheric agents, chemicals and moisture, reducing the risk of oxidation and corrosion.Thermal and electrical insulation: The plastic coating provides an additional layer of insulation, making the profiles suitable for contexts where superior safety performance is required.Impact resistance: plastic coating improves impact absorption capacity, reducing the risk of surface damage or deformation.Plastic coating guarantees uniform and fully customisable finishes, with a wide choice of colours and textures, making it perfect for applications where aesthetics are a key element. This process represents an optimal solution for those who wish to combine high technical performance with refined design, offering results that satisfy even the most demanding market requirements.

Large thicknesses

With an avant-garde approach and a constant focus on innovation, we have implemented new production facilities, expanding the processing possibilities towards large thicknesses. Thanks to this technological evolution, the company is able to produce metal profiles up to 4 mm thick, exceeding the previous limit of 3 mm. This upgrade allows us to expand our product range and offer new solutions to our customers, while maintaining the standards of quality and precision that have always distinguished us.We position ourselves as a strategic partner, supporting you with customised special profiles that aim to achieve a competitive advantage. Innovation, curiosity and creativity are the key words for the creation of innovative products and the consequent creation of synergies.Advantages for large thicknessesGreater strength: Profiles with thicknesses of 4 mm offer superior resistance to mechanical stress, ideal for applications requiring high performance.Impeccable precision: Even for large thicknesses, machining maintains high quality standards, with minimal tolerances ensuring perfect fit and durability.Cost optimisation: The use of thicker profiles reduces the need for additional structural reinforcements, optimising materials and processing time.With this technological evolution, we consolidate our position as a reliable and innovative partner for professionals requiring robust, customised and high-performance solutions

Download our catalogue

The variety, versatility, and quality of our metal profiles,

enclosed in practical and intuitive catalogs.