Perforation

Perforation

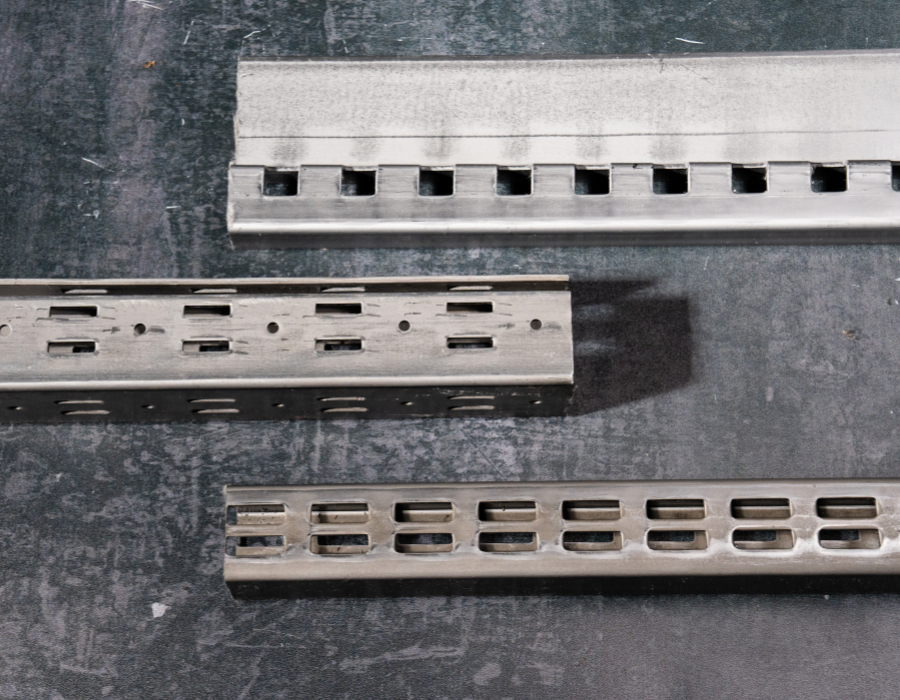

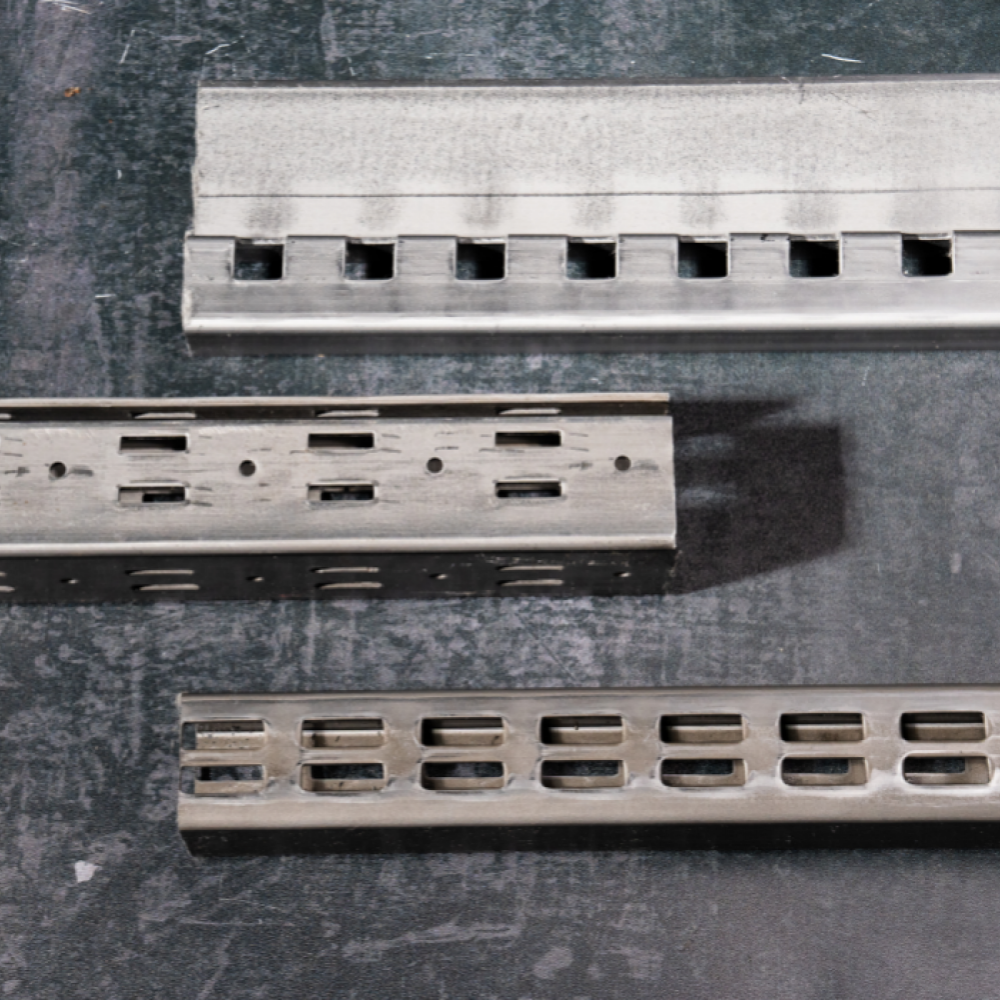

Strip perforation: precision and customization for every need

Strip perforationis an advanced technology we use to enhance competitiveness and reduce production times. This process allows for the creation of shaped and customized holes according to designs, completing the required profiles without the need for additional work. Thanks to high-performance machinery equipped with photo-cellular technology, we guarantee millimetric precision with decimal tolerances that meet the most stringent requirements. The applications are extensive: from uprights for shelving, electrical cabinets, and displays, to profiles for fences, movable and equipped walls, and photovoltaic systems. We can perform continuous pitch perforation, with or without pitch jumps, maintaining precise distances between head and tail as per customer specifications. Additionally, we offer laser perforation, ideal for jobs requiring an even more specific finish.

Advantages of strip perforation

- Production Efficiency: Reduced time thanks to a direct process without rework.

- Design Flexibility: Ability to customize holes and distances based on project requirements.

- Guaranteed Precision: Advanced machinery ensures tight tolerances and flawless machining.

With strip perforation, we provide a technological and highly customized service, aligning with our mission to create added value and synergies with our customer partners.

Download our catalogue

The variety, versatility, and quality of our metal profiles,

enclosed in practical and intuitive catalogs.