Profile rolling

Profile rolling

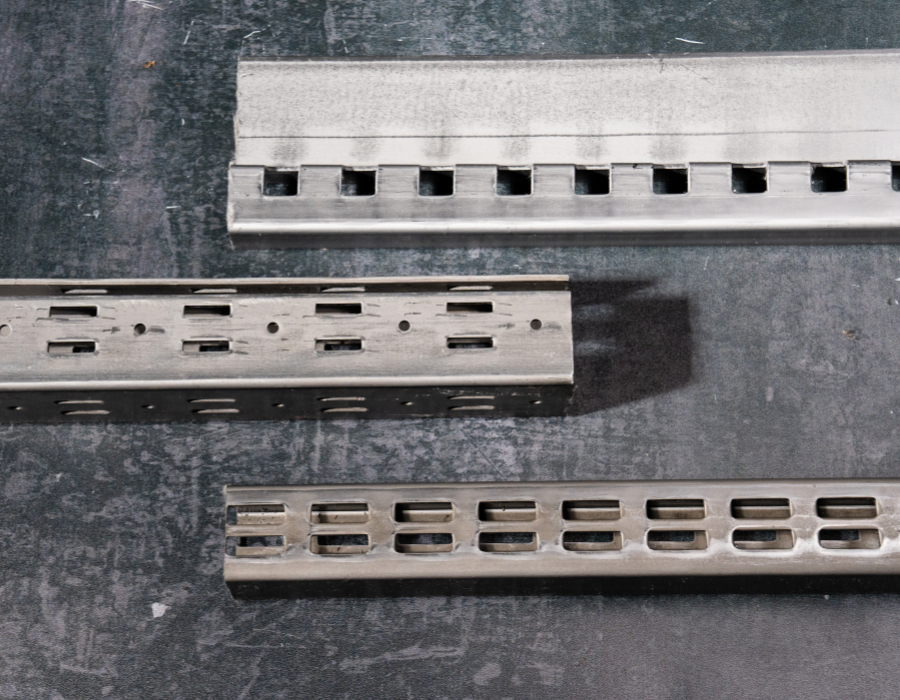

Advanced technology for highly versatile profiles: profiling that optimises

Profiling rolling is an advanced and efficient technology for the production of steel profiles, which guarantees precision and versatility. It allows strip thicknesses from 0.5 to 5 mm, lengths up to 27,000 mm and heights up to 100 mm to be processed. The process, carried out cold, progressively deforms the strip to the desired shape, maintaining or in some cases even improving the characteristics of the material.

Thanks to our innovative capacity, we produce more elaborate shapes than traditional methods, simplifying further processing and increasing the quantities produced. This results in profiles with optimised thickness, complex or variable height sections, optimising costs and making your production more efficient.

Profiling rolling advantages

- High accuracy and repeatability: precise and uniform profiles with minimal tolerances, thanks to cold forming that maintains constant dimensions and quality.

- Material optimisation: roll forming minimises scrap, improves steel properties and ensures sustainable strength, durability and efficiency.

- Design flexibility: this technique creates articulated and customised geometries, with variable thicknesses and complex sections, improving productivity and flexibility.

Ideal for high-volume production (from around 2000 metres), roll forming allows additional processing such as drilling, slotting, embossing or thread insertion directly in-line. The result is a highly competitive, cost-optimised range of possibilities.

Download our catalogue

The variety, versatility, and quality of our metal profiles,

enclosed in practical and intuitive catalogs.