Custom-designed profiles

Custom made profiles

Custom metal profiles: we bring your projects to life

Our custom metal profiles embody Profilsystem's philosophy. We don't use the term "standard" because we specialize in bringing completely customized ideas to life. Our custom steel profiles are designed to adapt perfectly to every engineering and manufacturing requirement.

Manufactured with the utmost precision and impeccable quality, our profiles provide optimal solutions for creating components and structures in various sectors. We guarantee the strength, durability, and adaptability of our profiles to a wide variety of industrial and architectural applications. The quality of our profiles stems from a meticulous process expressed in several crucial stages.

- Working method: based on collaboration, transparency, and mutual trust with our customers.

- Advanced design: we listen carefully to your needs in order to develop the desired product together, using the best software and the certified skills of our staff.

- Selected suppliers: we only work with reliable suppliers to ensure the excellence of our raw materials.

- Precision and flexibility: our machinery is constantly updated to guarantee the highest precision, with tight tolerances. Furthermore, the dynamism of our family-run company allows for direct relationships and rapid resolution of any issues, finding solutions in the shortest possible time.

Contact us now to send us your design and allow us to turn your vision into reality with our custom-made metal profiles.

No standards: tailor-made processing for customised metal profiles and sections

The key to our success lies in our ability to customize metal profiles, which we guarantee thanks to our wide range of specialized processes.

Our goal is to provide you with semi-finished or profiled products that are as complete as possible. This eliminates the need for further processing, saving you significant time and resources in your production cycle.

At Profilsystem, we are experts in defining cuts and shapes for custom profiles, making them as tailored as possible. Every process, whether it involves durable finishes such as plastic coating or precise customization through marking or pitch drilling, is carried out with extreme craftsmanship. This ensures the creation of high-quality, ready-to-use custom profiles.

A tailor-made process: from design to production of profiles

Our production process is entirely dedicated to special profiles and is designed to adapt perfectly to your specific needs. Focusing on quality and customization, we leverage our renowned experience and professionalism to carefully listen to your needs and structure a process that will lead to the creation of your customized profile.

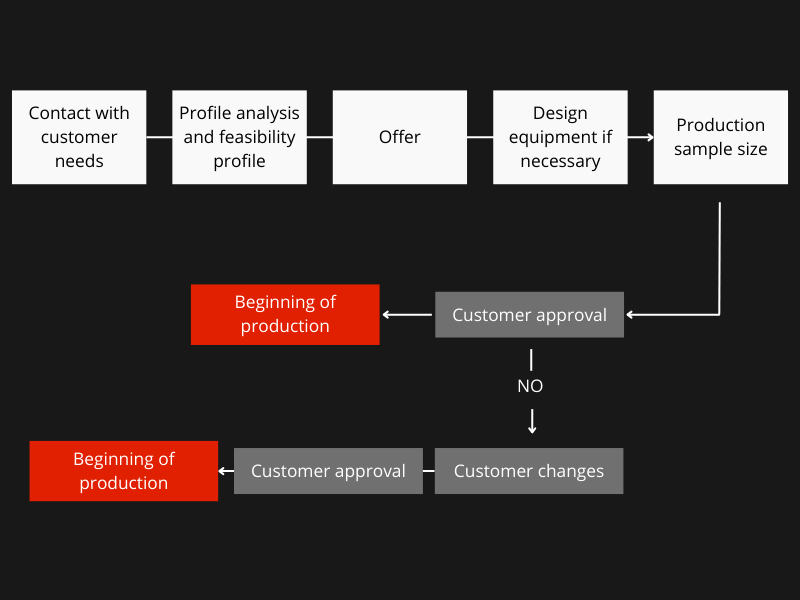

We put you, the customer, at the center of our focus, paying close attention to your needs and technical and production requirements. First, we listen to your requests and conduct an in-depth analysis of the technical feasibility of the project. Only then do we propose a solution tailored to your needs. We oversee every detail, from designing the equipment to creating samples, ensuring each stage meets the highest standards of precision and quality. Our precision and dynamism ensure a rapid creation process from design to implementation for new profiles. Once the samples are approved, we begin final production, ensuring full compliance with your expectations and prompt delivery.

Thanks to our use of certified materials and the ability to customize each project, we provide the ideal balance of innovation, robustness and adaptability. Our cornerstones of customer relations, speed, and precision allow us to create innovative products and offer impeccable service, giving our partner customers a competitive advantage.

When you rely on us, you can rest assured that you will receive a tailor-made product on time with zero stress.

Precise at every stage

Customer contact

The process begins with the initial contact to understand the customer's specific needs. This phase is crucial for gathering all the necessary information and establishing clear communication.

Profile analysis and feasibility

Next, a technical analysis is conducted to evaluate the requested profile and assess the project's feasibility. This step helps identify potential technical challenges and prepare an appropriate solution.

Offer

After completing the analysis, a personalized offer is prepared. This includes defining costs, delivery times, and production terms.

Equipment design

If required, custom equipment is designed and developed for production. This ensures that the customer's requirements are met with precision.

Sample production

Before starting full-scale production, a sample is produced. This serves to verify the quality and compliance of the product with the customer's specifications.

Customer approval

The sample is submitted to the customer for approval. If the customer is satisfied, the process moves to the next phase. Otherwise, necessary adjustments are made to meet their needs.

Production start

Once final approval is obtained, full-scale production begins, following the agreed specifications.

Delivery of the supply

The products are delivered to the customer in accordance with the agreed timelines and conditions. Once the delivery is completed, feedback is requested from the customer to assess overall satisfaction.